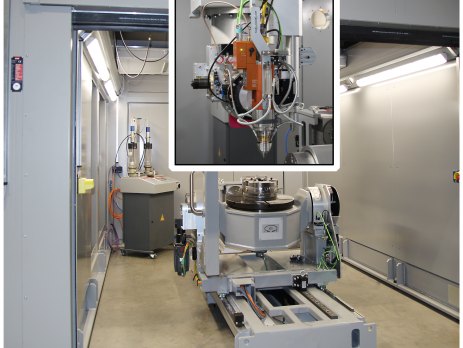

Arnold Ravensburg recently delivered a 3D laser system for build-up welding to a well-known Swiss group. The flexible laser system should enable the customer to try out other laser applications in addition to powder deposition welding. With one function, wire welding of 3D contours, the customer can quickly and alternatively check which is the better process for the respective application without major retooling. The wire welding head was supplied by coaxworks GmbH from Dresden. A movable turn-swivel table with a load of more than 500 kg extends the NC-controlled 5-axis system by two additional axes. The total of seven NC axes can thus be transformed in various combinations in space and enable maximum flexibility in the processing options. A large lifting gate allows the best access to the internal system components as well as for loading the rotary-swivel table. An additional opening in the system roof is used for loading with an indoor crane. Within the beam guidance there is a zoom collimation optics which can automatically adjust different beam diameters and focus positions for process optimization. Further applications were already planned during the construction phase, so that standard welding heads and cutting applications can also be retrofitted to the machine, for example.