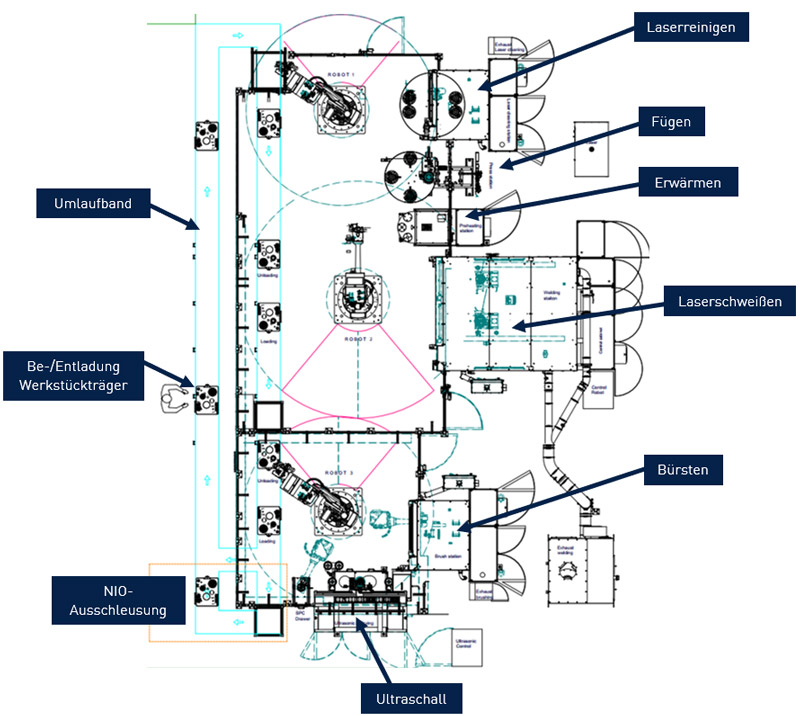

Before laser welding, the components come to the production line in a wide variety of shapes. Below is an example of a layout with a component feed using conveyor technology, based on movable workpiece carriers. A wide variety of operating modes such as series operation, rework, random sampling, ejection of NOK components, running empty and other operating states result in tedious programming times with complex commissioning and long testing times. Due to the size of the system and cycle time requirements, several robots or handling units are required for the automated process.

Customers often expect that the complete production line itself Automatically can be converted to other workpiece types without operator intervention. However, if there are large differences in the component geometries, this requirement cannot always be reasonably implemented, or only with disproportionate effort.