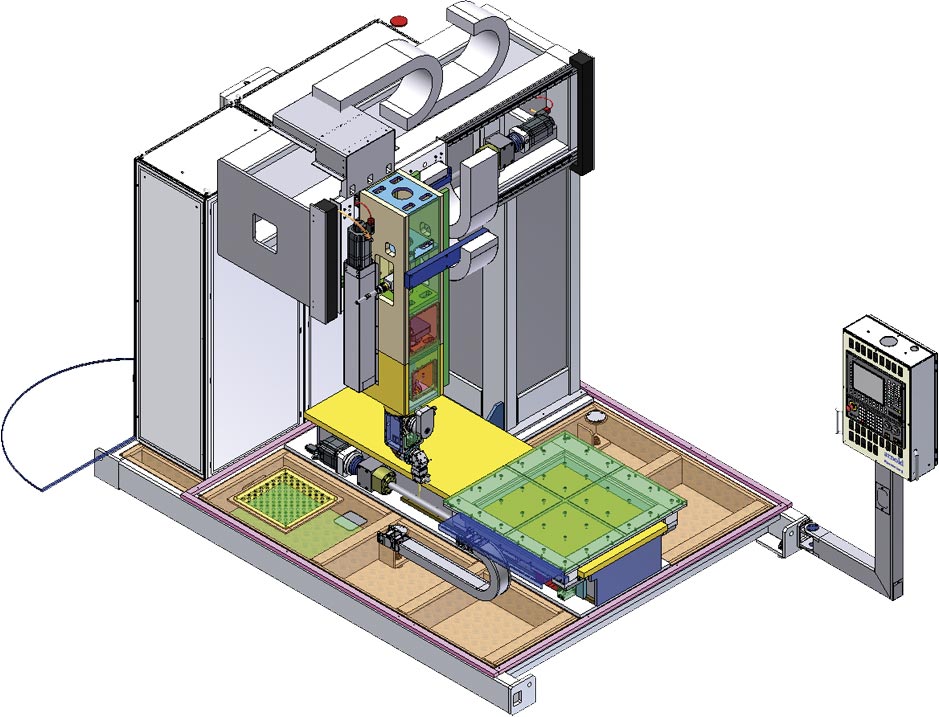

3D laser center flex cell

With the term flex cell, we associate a wide range of laser processing options. The 5-axis laser processing center offers large travel paths on a relatively small area. All components are built on a base frame and the system can therefore be dismantled without dismantling and reassembled at the customer's site in a short time. The 5-axis kinematics can be implemented through various combinations of the travel paths of the optics and the workpiece. As standard, we deliver the machining center with the processes laser welding, laser cutting and laser deposition welding.

Several options such as welding with wire, device constructions according to component specifications, scanner optics, crane loading of workpieces or robot loading enable both series operation and manual loading of workpieces.

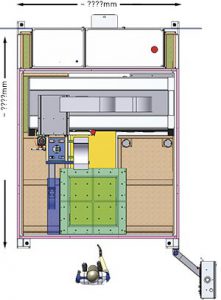

Layout of the 3D laser center flex cell

A solid and stable construction and basic components as welded assemblies are characteristic of Arnold's laser systems.

On the portal bridge, the Z-axis moves with the integrated processing optics in the horizontal and vertical directions. The optics can be expanded with rotary and swivel axes to form a 5-axis laser machining center. The table assembly can also optionally be supplied with rotary and swivel axes. The maximum expansion is 7 NC axes.

All components, including the control and media cabinet, can be placed on a base frame and enable the system to be shipped without major dismantling.

Videos

Laser 3D flex cellVideo

Laser 3D flex cellVideoFrom 3D printing to complex laser welded parts to 3D laser processing of large components. The flex cell can do more than just standard and offers different laser processes in one system.

Technical data

| 3D laser center flex cell | ||

|---|---|---|

| Footprint |  |

|

| Traverse paths / speed | X = 750 - 1200mm (60m/min) Y = 250 - 1200mm (60m/min), Z = 250 - 750 mm (30 m/min) C = ± 200° (300°/s) B = ± 100 (300 ° / s) |

|

| Dimensions (L x W x H) | at least 1350 x 1620 x 2675 mm - max. 3540x2645x4800mm |

|

| component size: | -depending on traverse paths | |

| steering | Sinumerik 840 D SL | |

| Beam source | Solid state laser (standard) - CO2 laser (option) | |

| Processes | All laser applications in 2D and 3D | |

| laser power | > 1 kW | |

| Positioning accuracy | X, Y, Z +/- 0,01 mm (VDI 3441) |

ADDITIONAL INFORMATION

We will be happy to send you information about this laser processing system (PDF) as well as an overview of our laser systems to your email address. For further questions and information, please call our sales department at

Phone +49 (751) 36169-199 or by mail Sales@arnold-rv.de